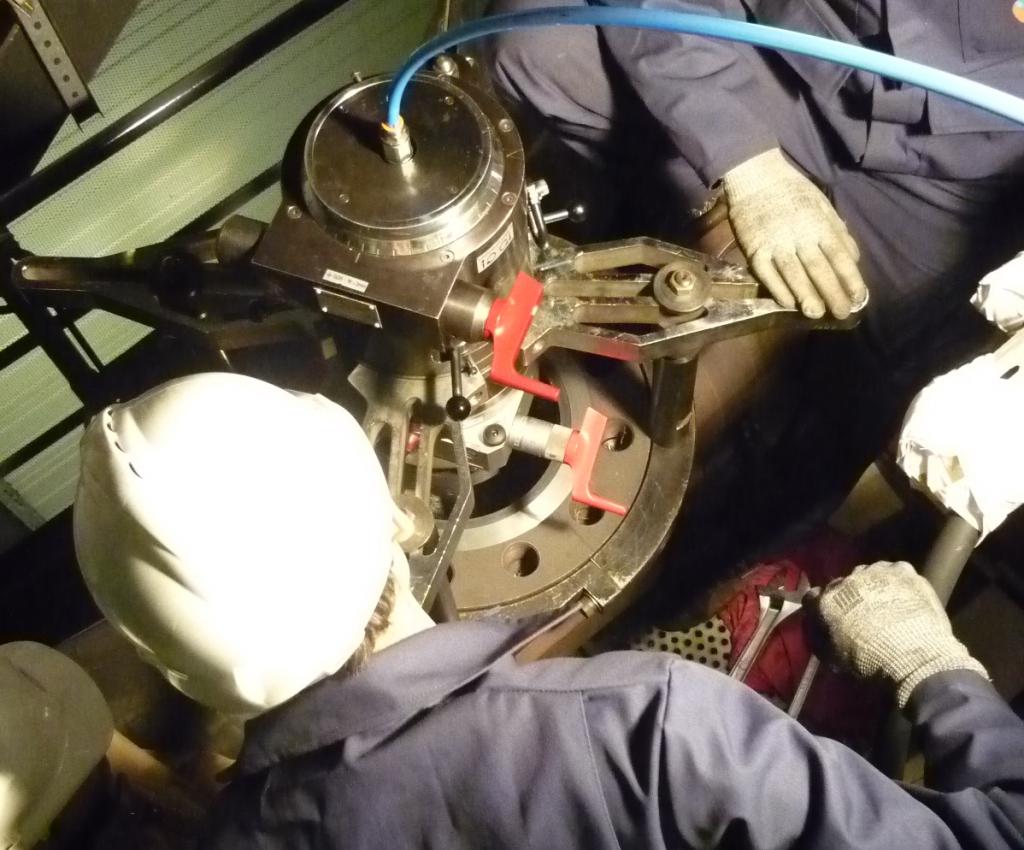

John Cockerill Services designs and manufactures processing equipment to guarantee safety during the evacuation and treatment of active or contaminated waste. The processing of activated or contaminated parts consists of removing the parts from a nuclear zone, while guaranteeing the protection of the environment and the personnel, through confinement in a hermetically sealed area and control of radioactive radiation.

Processing which mainly involves the Upper Internal Elements (UIE) of nuclear reactors. Very close to the fuel, this equipment participates in guiding the control clusters and thus in the control of activity within the reactor, and thus become activated, requiring specific processing in order to be able to be manipulated outside of the nuclear zones. This involves parts of varying sizes with a very high level of radioactivity and stored in the baths.

With the benefit of long experience in the nuclear sector, John Cockerill Services has made this a speciality and can thus offer a wide range of adaptable packaging and services personalized according to needs:

- Internal modularity according to the geometry of the parts to be processed (all types of guidance tube clusters);

- Dimensioning of packaging adaptable to all reactors (900, 1300 or 1450 mw);

- Dimensioning for radioprotection and mechanical resistance in order to guarantee safety

- Variable quantities of parts to be stored in the interior of the packaging (up to 33 re-formed guidance tube clusters);

- Internal and external training in use of the packaging

- Drawing up and supply of operating kits

- On-site n storage of used equipment during replacement operations while waiting for specific handling

- Transport away from the site in type A containers

In addition to these processing containers, John Cockerill also provides operating kits enabling commissioning on site and by the client: transport framework, rocking levers, walkways, drying systems, additional protection tools and checking for hermetic sealing after closing the packaging…